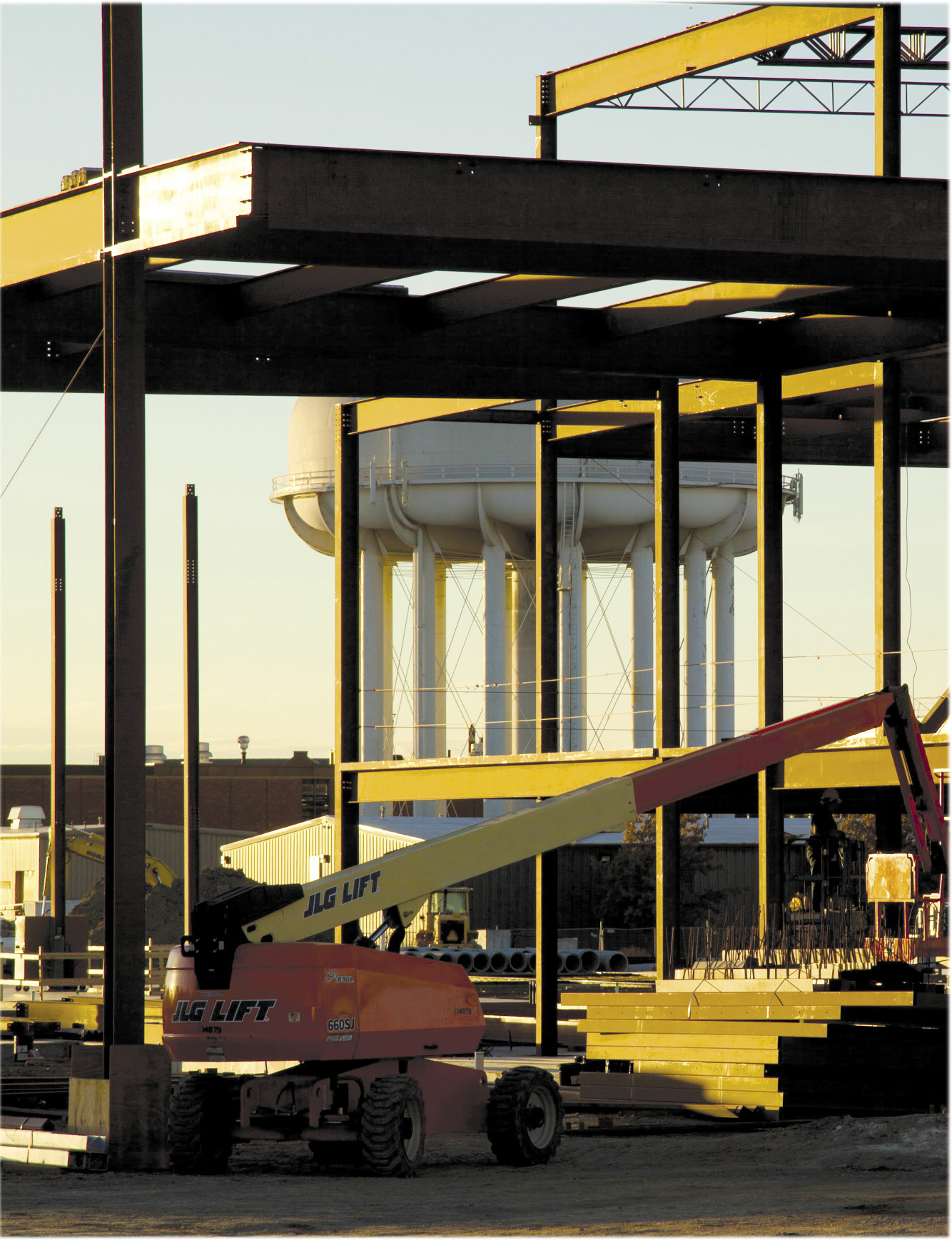

Steel and concrete are changing the landscape of the southeast quadrant of the university’s main campus as the first two innovation buildings take shape.

There’s the 90,000-square-foot building that Crossland Construction Co. is putting up to enable Airbus to move some 400 employees and its Wichita engineering center from Old Town to campus. (See “Location, Location, Location” for more about the Airbus-WSU partnership.)

Construction has also begun on the $43 million Experiential Engineering Building — which, thanks to a partnership between WSU’s National Institute for Aviation Research and Dassault Systèmes, is set to house an advanced manufacturing center that will open up 3D horizons for researchers, students and industry pros alike.

“Dassault Systèmes is an essential partner in WSU’s Innovation Campus,” says John Tomblin, WSU vice president for research and technology transfer and NIAR executive director. “The 3DExperience Center will provide the capability to go from the concept, to a full experience of the idea, to the realization of seeing that idea being developed and manufactured. It will be a core enabler of additive manufacturing in aerospace, as well as other industries.”

Additive manufacturing promises companies the ability to design any shape without restriction. Manufacturers can reduce waste by up to 90 percent and eliminate mistakes that affect quality and cost. “Additive manufacturing has high potential for aerospace and other industries and goes far beyond just 3D printing,” explains Michel Tellier, vice president, aerospace and defense industry, Dassault Systèmes. “It requires an understanding of new materials down to the molecular level, how those materials perform under any scenario, how they can be expediently and cost-effectively manufactured and how each piece of the ultimate system can be certified.”

With its focus on fostering advanced product development and manufacturing next-generation materials and technologies, the 3DExperience Center is expected to open in the fourth quarter of 2016. The center will employ students and up to eight staff from Dassault Systèmes, a global company serving some 190,000 customers in 12 industries and 140 countries. The center will be available to industry and for university research and coursework.

“The whole learning model of classroom learning, practicing in a lab environment and performing production work with one of the industry partners is embodied in the 3DExperience Center,” says Jeff Smith, director of the Ideas Lab, aerospace and defense industry, Dassault Systèmes. “Students will be able to engage in the future of advanced product development and manufacturing.”

Using Dassault Systèmes’ 3DExperience platform and brand applications, the 3DExperience Center will encompass such activities as the development of new engineered materials; the simulation and optimization of materials, additive manufacturing processes and systems; Multi-Robotic Advanced Manufacturing; certification of the end-to-end process, integrating various levels of complexity and scale — from specific molecular material to the whole product, from specific manufacturing process to integrated and global production processes, and from system to systems of systems, with the 3DExperience platform.

Funding for the center’s laboratory equipment was provided by a $1.9 million U.S. Economic Development Administration grant awarded in 2014. The equipment is being configured and tested in NIAR’s Robotics and Automation Lab at the National Center for Aviation Testing. Dassault Systèmes and WSU/NIAR have long collaborated on the development of innovative aviation projects. Most recently, the two entities worked together to finalize Dassault Systèmes’ “Passenger Experience,” an industry solution developed to better meet the service expectations of customers; the initiative launched in June 2015.

“The new center will leverage the 3DExperience platform’s immersive and robotic applications, and Dassault Systèmes’ expertise in materials and simulation,” Tellier says. “Tomorrow’s materials will push the evolution of airplane design, production and operation into a new era.”

— From NIAR’s July 27, 2015 news release “Dassault Systèmes partners with NIAR on advanced manufacturing center”

The 3DExperience Company

Headquartered since 2008 in the southwestern suburbs of Paris, in Velizy-Villacoublay, France, Dassault Systèmes is a European multinational software company that develops 3D design, 3D digital mock-up and product lifecycle management (PLM) solutions.

A subsidiary of the Dassault Group, Dassault Systèmes was created by Avions Marcel Dassault to develop a new generation of computer-aided design (CAD) software called CATIA, as well as to explore the computer-aided manufacturing (CAM) market, pursuits that eventually led to the company’s core 3D CAD/CAM software.

Today, Dassault Systèmes develops and markets PLM software solutions and services that support industrial processes by providing a 3D vision of the entire lifecycle of products. In this way, Dassault Systèmes helps businesses transform the way their products are designed, produced and supported.

The company has some 190,000 customers in more than 140 countries and in almost all industries, including, in addition to aerospace and defense: architecture, engineering and construction, high technology, industrial equipment, energy, marine and offshore, life sciences, natural resources, finance and corporate services, transport and mobility.

In 2011, to complement its European headquarters in France, commonly called the 3D Paris Campus, Dassault Systèmes established a key base in the United States. Located in Waltham, Mass., just west of Boston, it has taken on the name 3D Boston Campus.

For more information, visit www.3ds.com.