What collective could be summoned to challenge the disintegrative forces massing to imperil our city’s economic well-being — indeed, readying to invade our own frail-fleshed human bodies? Certainly no ordinary partnership of entities! But when the crossing of intellectual powers and scientific collaboration brings into being the mighty Captains Future — well, that’s a different story.

Wichita State’s David McDonald and his team of collaborators have embarked on an adventure not unlike those taken up by the pulp hero Captain Future, a brilliant scientist who roams the solar system vanquishing villains and righting wrongs.

Although McDonald’s Captains Future remain Earth-bound, they nonetheless adventure through vast, new territories — masterminding a plan to unite aviation and medical technologies. It’s a first step in diversifying Wichita’s aircraft manufacturing base and creating thousands of new jobs in the Air Capital.

With the same dashing spirit of innovation as those who built the airplanes and companies that led to the city of Wichita’s most famous moniker, McDonald, WSU associate provost for research and a biologist by academic training, came up with the idea of melding R&D pursuits in aerospace and medicine, with the goal of inventing and improving medical devices and implants. He knew that WSU and, in particular, the National Institute for Aviation Research at WSU have stellar experience in, as he explains it, “working with regional manufacturers to help them solve the technical problems associated with their products.”

It made sense to him that pairing that expertise with Via Christi Health System’s prowess in bioscience research would pay off big — especially in a city that’s one of only seven composite manufacturing clusters in the world.

McDonald is lead author of a 100-page business plan submitted to the Kansas Bioscience Authority that requests a $31 million, five-year grant for the construction of a Center of Innovation for Biomaterials in Orthopaedic Research. CIBOR would house experts and practitioners who share the mission of developing useful medical devices from biomaterials similar to the composites used in aerospace manufacturing — those lightweight, pliable yet super strong materials that revolutionized the industry.

“I’m excited about this project because of the huge promise it holds for strengthening our regional manufacturing cluster,” McDonald says. “Of course, the ultimate goal and advantage is to bring new treatment options to orthopaedic surgeons and their patients. This will improve the quality of the lives of those who would otherwise be living with pain or physical limitation.”

McDonald, who first began talking with engineers and surgeons about his idea two years ago, now calls on the diverse talents of his team to brainstorm outcomes and iron out details. Dubbed the “Idea Team” by local media, the forward-thinking group is comprised of McDonald, who provides expertise from the side of academia for developing the business case for CIBOR, and five other individuals, each of whom brings a special sphere of knowledge and influence to the project.

John Tomblin, NIAR executive director, has the skills to design the next generation of composite materials and the contacts with manufacturers to “move those materials from the lab to the production facility,” McDonald says. Tom Aldag ’83, NIAR director of R&D, is also an expert on advanced composite materials.

From Via Christi Regional Medical Center, Paul Wooley, microbiologist and immunologist, delivers the “scientific savvy” to deal with the challenge of designing new and improved orthopaedic devices, McDonald says, while David McQueen, an orthopaedic surgeon and inventor of a knee replacement used worldwide, is the team member who perhaps has the most purely inventive mind. And Mike Good is Via Christi’s veteran director of research business operations with more than two decades of experience.

“I’m inspired to work with these individuals,” McDonald says. “I can honestly say that we’ve never had a meeting that failed to yield useful, important and achievable goals.”

Aldag was so inspired by the idea of applying the aerospace industry’s technical and composites know-how to helping invent medical tools that the then-Cessna engineer couldn’t remain on the periphery. After a job offer from NIAR head Tomblin, he left Cessna to join the team. “I wasn’t looking to leave,” he says. “Cessna’s a great place to work, but after I heard about this — it just makes so much sense. It’s a perfect match.”

of a team anticipating the

approval to construct a

Center of Innovation for the

Creation of Biomaterials in

Orthopaedic Research.

The veteran engineer, pilot and composites ace has worked at NIAR for about a year and a half now, and his interest in the unfolding research partnership between aviation and medicine hasn’t diminished a whit. In fact, as the time nears for the Kansas Bioscience Authority to approve or decline the $31 million grant for CIBOR (notification is expected in early 2009), his interest in the project ratchets up.

Tomblin is known for being far-seeing yet brutally practical. For instance, when the idea surfaced of making millions for Wichita by engineering a new type of hip replacement using composites, Tomblin pointed out that it would likely take a decade to gain Food and Drug Administration approval for the invention — and that the Kansas Bioscience Authority would want a faster payoff on its investment, should it approve the grant.

“The strategic plan for CIBOR is to link two of the largest industrial sectors that exist within Kansas: manufacturing and health care,” Tomblin says. “Using advanced materials and manufacturing methods, Kansas has a unique opportunity to become a world leader in this developing area. Initially, we hope this partnership will take advantage of relatively simple medical devices that have the ability to greatly improve current instruments and procedures.

These include introducing and incorporating X-ray transparent orthopaedic operating tools in practice, as well as things such as lighter and more functional stretchers and operating tables. In the long term — which would work in parallel with these efforts — would be to investigate the use of bio-compatible composite materials for the replacement of current day metallic implants.”

Wooley offers even more detail about what might constitute successful outcomes to the team’s work over time. “The establishment of CIBOR as a physical entity is the key to the short term success,” he says. “This will allow scientists, surgeons and companies an arena to discuss issues and develop new devices. The five-year goal includes the production of FDA Class I and Class II devices, such as novel instruments and external fixation devices.”

Looking further down the road, he sees some amazing developments. “The ten-year horizon includes implantable devices, with a specific focus on hip and knee replacement,” he says. “After that, I foresee a broadening field that includes implantable organ replacements, such as liver and pancreas.” For that level of intricate interaction with the human body, any composites used would need to be extraordinarily compatible with the body’s natural materials — something Wooley and his colleagues, some from Wayne State University in Detroit, have already turned their scientific attention to.

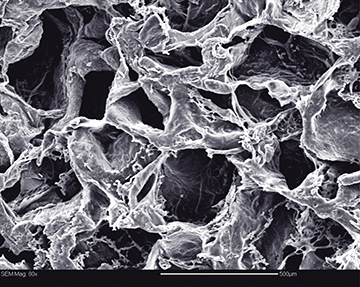

Composites, Wooley explains, get along better with the body’s inner workings than metal implants do because they “allow us the capacity to include natural bone materials, such as hydroxyapatite, in the mix. They also can be engineered to match the physical properties of bone, and don’t corrode and leach ions the way metal implants do.”

Before being recruited to Wichita, Wooley was research director in the department of orthopaedic surgery at Wayne State, where he worked with King Hay Yang, director of the bioengineering center, and Haiying Yu, a grad student training with Wooley and Yang. Yu developed a composite incorporating hydroxyapatite, which shows promise — and, Wooley reports, “Haiying will be joining the team in Wichita at the end of the year.”

is of a bio-compatible composite

that includes the natural bone mat-

erial hydroxyapatite.

One lure to Wichita for these scientists is NIAR. “I think everyone is impressed by NIAR,” Wooley says. “It’s Disney World for engineers. They have the best instrumentation and scientists available in the field. But it goes beyond that.”

He explains that a number of U.S. universities seem to operate on the premise that “good basic science and creating start-up companies will answer the world’s problems, but that is fundamentally naïve and serves to enrich a few venture capitalists. (The team) understands that much of device development is driven by the end-user — in our case, surgeons and implant manufacturers. They have research problems that require innovation and integration of novel materials and approaches, but they know that basic science, however brilliant, is speculation until it helps the surgeon or the patient.”

Wayne State, like Wichita State, takes seriously its urban serving research mission, so Wooley’s comments dovetail with WSU Provost Gary Miller’s articulation of what that mission means: “One of the elements of the current national critique of American higher education is that it is still discovering how to deploy its great power of innovation in direct support of economic growth and stability. Traditional approaches of research are extremely important, and WSU is very much involved in such basic research.

“But we also bring to the community another approach, framed in business time and directed at current business problems. We measure the success of the WSU-NIAR model of research application in real economic metrics like increased jobs, manufacturing capacity and income. The CIBOR developed jointly with Via Christi is an excellent example of our approach.”

Miller adds, “Nearly every imperative of the human condition plays out within the great diversity of people, culture and commerce in cities. This is more and more the case as the world becomes more urbanized. There is no question in my mind that universities situated in urban environments have the greatest opportunities to build the social, economic and educational models of the future.”

Wichita State: composites, biomaterials — and far, far beyond!

WSU & The World

Provost Gary Miller hosts “Wichita State & The World,” a TV series broadcast on Channel 13. Lou Heldman, WSU Distinguished Senior Fellow in Media Management and Journalism, created the series.

Provost Gary Miller hosts “Wichita State & The World,” a TV series broadcast on Channel 13. Lou Heldman, WSU Distinguished Senior Fellow in Media Management and Journalism, created the series.

Channel 13 primarily carries research and lecture programs that originate at other universities. Heldman thought a locally created show could attract viewers and promote Wichita State, especially given its charge of being the only urban serving research university in Kansas.

The first episode, which features J. David McDonald, WSU associate provost for research and dean of the graduate school, was aired Sept. 7. More episodes are planned. Elizabeth King, president and CEO of the WSU Foundation, is featured guest on the second program; Greg Meissen of the WSU Center for Community Support and Research and Deborah Ballard-Reisch, WSU’s Kansas Health Foundation Distinguished Chair for Strategic Communication, are guests on program three. The fourth episode will be about WSU associate professor Les Anderson and Wichita State students who visited Greensburg, Kan., to create a series of stories on how that town was rebuilt after a devastating tornado.

Heldman says he’s pleased with the high quality of work done by the university’s Media Resources Center and likes the show’s placement on Channel 13, which sits right next to the established network channels.

“Channel 13 is a prime piece of real estate,” he says.

— David Dinell